Filter Press Plate Manufacturing

Custom, Made-to-Order Products

5-Year Warranty on Our Frame Works

Team of Certified Welders

Hours:

Request Quote

Hero Request Form

Thank you for contacting us.

We will get back to you as soon as possible

Please try again later

Filter Plates Backed by Over 150 Years of Experience

Plate configuration--the selection of the correct filter element--is absolutely critical to filtration applications. Among determinant factors in plate configuration are cake thickness and filtration area, the temperature of the filtrate, the need (or lack of need) for temperature control, volatility of the filtrate, viscosity, and so on. The particular combination of these factors in any application will determine compatible materials of construction. Cost is also a consideration here. The multiplicity of factors inherent in any application makes flexibility of plate construction material a real advantage to anyone designing a filtration system.

At D.R. Sperry, we pride ourselves on our competitive pricing, 5-year framework warranties, superior customer service, and well-established team. We even offer fast response times and flexibility for our custom, made-to-order products perfectly tailored to your needs.

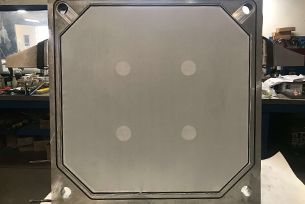

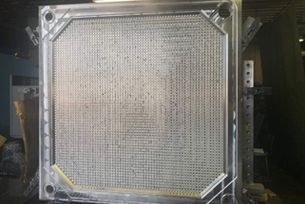

Flush Plate

Lug Plate

A special type of flush plate and frame is the lug style plate. Lug style plates are used when the application demands frequent changes of filter media (e.g. the processing of shellac), and minimize labor in that they eliminate problems of media alignment.

Recessed Plate

Leakproof Plate

A special gasketed type of recessed plate. Imperative in the filtration of volatile or hazardous materials, they are often used to reduce product loss or simply to effect a cleaner environment.

1000mm

1000mm 316 stainless steel recessed chamber plate, gasketed and polished.

1000mm

1000mm 316 stainless steel recessed plates, gasketed with Teflon filter media.

1000mm

1000mm aluminum recessed gasketed and heated plate.

1225mm

1225mm aluminum heated gasketed recessed plate.

316mm

316mm filter plate.

630mm

630mm aluminum plates and frame.

762mm

762mm aluminum heated plates.

762mm

762mm Aluminum heated plates for textiles

Fabricated A36

Fabricated A36 steel plate.

McWong 48

McWong 48 plates.

Heated Aluminum Plates

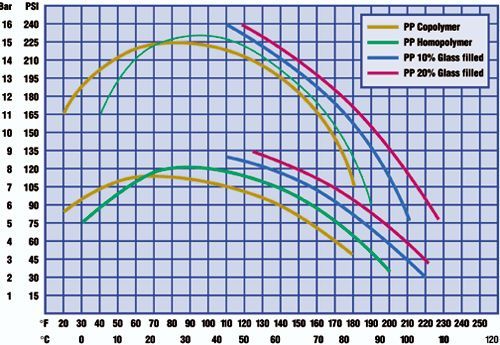

PRESSURE/TEMPERATURE CHART

The pressure chart is a guideline for filtration or wash pressures at certain temperatures.

Temperature differentials during a cycle of more than 20 degrees F can induce thermal shock and plate failure.

Chemical composition of the slurry can reduce operating parameters of filter plates. Contact the factory for chemical resistance guidance.

available materials

Listed below are the materials from which D. R. Sperry manufacturers filter press plates. The charts indicate current Sperry plate patterns by plate style, material, and size of filtration area. These charts reflect standard Sperry plates and do not include special plates which Sperry can produce and which may be indicated for your application.

| Cast Iron | Aluminum (steam-heated) Teflon ® coated |

| Cast Iron (steam-heated) | Polypropylene |

| Cast Iron-Heresite ® coated | 10% glass-filled Polypropylene |

| Cast Iron-galvanized | Hi-temp glass-filled Polypropylene |

| Cast Iron-lithcote | Hastelloy ® B (heat-treated) |

| 304 Stainless | Hastelloy ® C |

| 304 Stainless (steam-heated) | Ductile Iron |

| 316 Stainless | Ni Resist |

| 316 Stainless (steam-heated) | Kynar ® PVDF |

| Cast Iron-nickel coated | Bronze |

| Aluminum | Nickel Iron |

| Aluminum (steam-heated) | CI-Firmacoat |

Learn More About D.R. Sperry

Serving the Aurora, IL area. D.R. Sperry specializes in filter presses, plates, and media. Founded in 1868. 5-year warranty on our frame works. Team of certified welders. Call today.

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

Share On: